BUSINESS AREA

BUILDING A BETTER FUTURE THROUGH CONVERGENCE

Display Materials

We are always doing our best to develop diverse new products which will lead the future of the next generation display market.

Soulbrain’s Display Materials Division is providing a stable supply of high-tech chemical materials and parts, and we are leading the development of the display industry through development of products leading changes in the process. We are domestically manufacturing functional chemical materials used in the manufacture of LCD and OLED panels, as well as key components of panels including thin glass and cell scribing.

Display Materials Business

Etchant

Etchants for display chemically or electrochemically etch metals and non-metal materials, and are used in the process of wire formation for LCD and OLED displays. In the case of the LCD industry, etchants are made up of Ammonium-based (H2O2) etchants mainly used for the etching of copper wiring, oxalic acid-based etchants for etching ITO, BOE-based etchants for etching Si-based thin films, and so on. In particular, there is increasing demand for functional etchants achieving goals such as process ability improvement through price reduction.

Major products

- Copper Etchant

- BOE Etchant

- ITO Etchant

Product Examples

LCD/OLED TV

Notebook PC

Monitor

Smart Pad

Mobile Phone

Vehicle Display

Product Manager

-

Moosung Sim (Manager)

-

Sangbeom Kim (Manager)

Display Materials Business

Organic Material

Materials used in the manufacturing process of color filters, the key component of TFT-LCD panels, include black matrix and black column spacers for the realization of vivid colors, as well as organic insulating films for the planarization ton improve the TFT performance. Through technical cooperation with Mitsubishi Chemical, we have acquired technology for in-house manufacture of organic materials for color filter manufacture, and we are focusing on strengthening our product competitiveness through millbase localization. Currently, we are working to develop organic materials for OLED.

Major products

- Organic EL for OLED Inkjet

- Bank for OLED Inkjet

- Black Bank for OLED

- Black Column Spacer for LCD

- Black Matrix for LCD

Product Examples

LED TV

Notebook PC

Monitor

Mobile Phone

Automotive

Product Manager

-

Wonjae Choi (Manager)

Display Materials Business

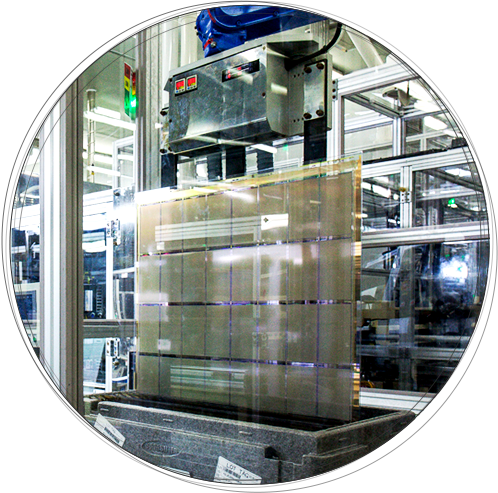

Thin Glass (OLED)

In the process of OLED panel manufacture, through our efforts for stable supply and our independant technologies for Thin Glass, making the front and back glass substrates thin, and for the scribing process which cuts each panel into individual cells, we provide our customers with a one-stop solution. By introducing the vertical spray method into the slimming process, we have greatly improved the productivity and quality of our products, with the characteritic of allowing selective etching of the front glass through employment of various masking technologies.

Major products

- 0.2 mm panel

- 0.3 mm panel

- 0.4 mm panel

Product Examples

Notebook PC

Smart Pad

Mobile Phone

Product Manager

-

Cheol Kwak (Team Leader)

mssim@soulbrain.co.kr

mssim@soulbrain.co.kr